GE_Tallawarra Flexi Suite(FS4) Installation 2018

Flexi Suite (FS4) Installation and Tie-in

| Client | Energy Australia, General Electrics |

| Location | Tallawarra Power Station (Energy Australia) |

| Job Title | Flexi Suite (FS4) Installation |

| Service | Specialised Welding (Gr. P91) & Fabrication |

Scope of Work

Flexi Suite Pipe Welding (Gr. P91) / Fuel Gas Modification

Condensate Drain Tie-in / Local Pipe supports / Hydraulic Test

Project Resourcing

Workshop personnel included Coded Welders and Boilermakers. The support team included Project Management, Quality Management, Project Engineering and Project Supervisor.

Project Achievements

We’ve proudly completed the project with high standard performance on schedule.

Due to the nature of the high-pressure pipe installation, there were high standard requirements in Safety, Qualify and Project & Schedule management.

All procedures were qualified and approved by International and Australian standards prior to the project commencing

- Zero (0) Lost Time Incident during the project (3,050 MHRS)

- Zero failure rate on all welding (108 welding joints- ASTM A335, P91 Grade)

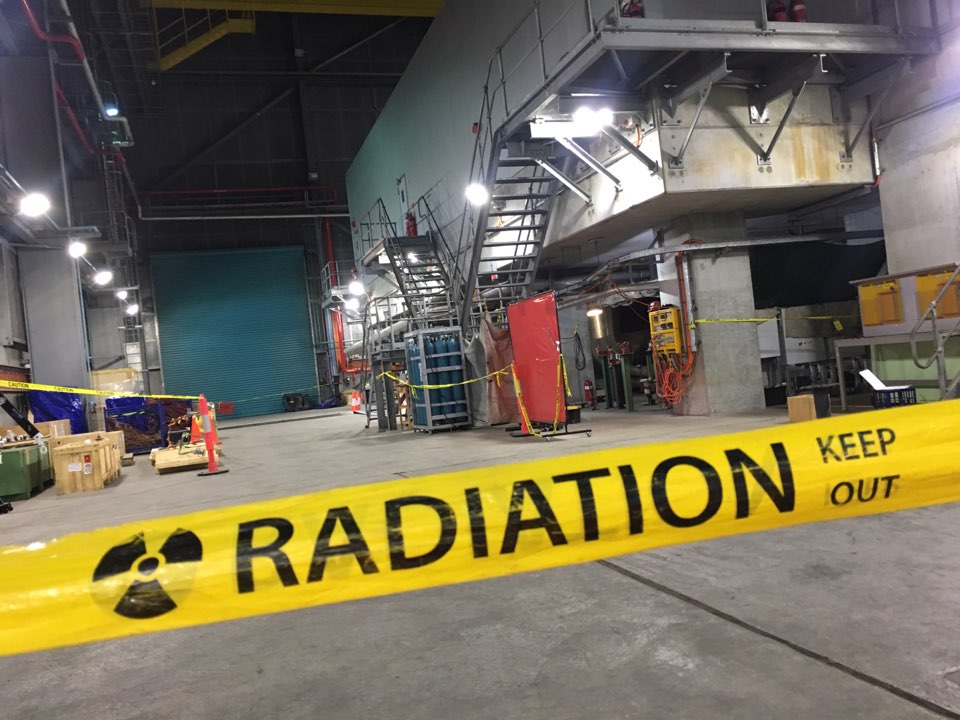

- 100% Radiology Test (RT) conducted

- Project delivered on time and on budget even with the additional scope of work

- Complete conformance to AS1210-2010 Class 1

- Protech Welding Pty Ltd worked closely with the client nominated International Welding engineer/ consultant to ensure all project quality requirements where exceeded for the duration of the project

Activities

- Extensive interaction with our client to ensure the quality of the finished product was in line with practical requirements, such as;

- Site Survey, Material Receiving Inspection, Addition Purchase Order & Fabrication

- Project and quality management

Project Images