EA TALLAWARRA POWER STATION EGH/ HRSG REPAIRS

EA Tallawarra Power Station EGH / HRSG repairs

Client Energy Australia

Location Tallawarra Power Station in Yallah, NSW

Job Title EGH / HRSG repairs

Service Welding / Heat treatment / Equipment and tool supply

Scope of Work

- IP Bypass Valve Replacement (P91)

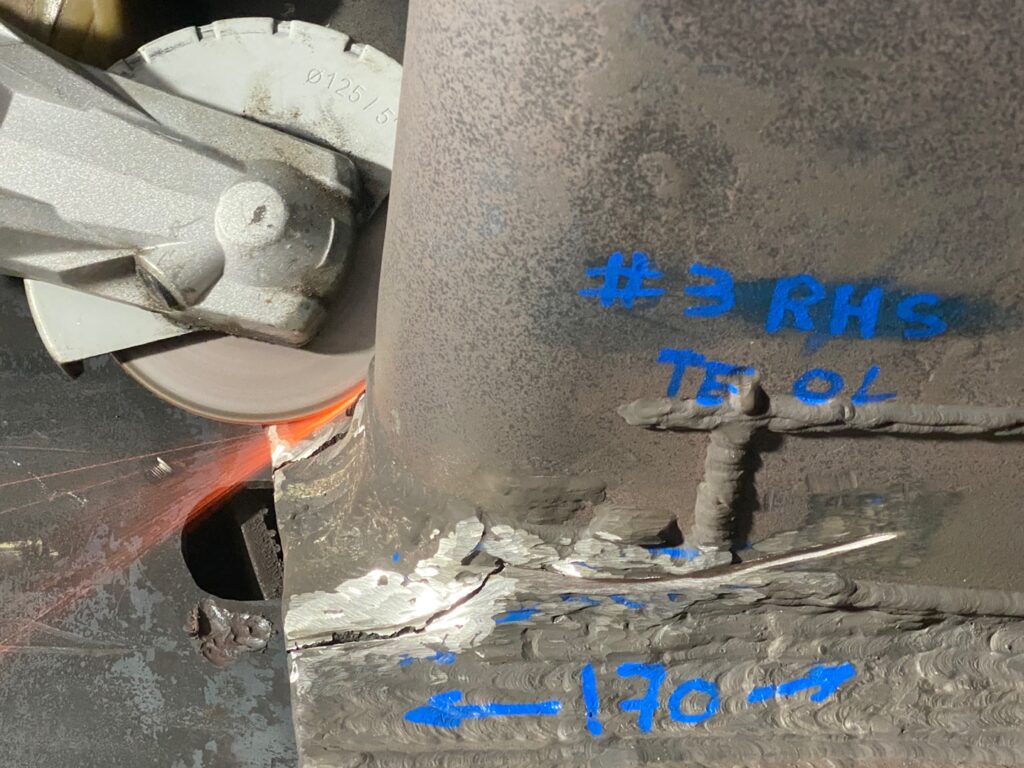

- Condenser Strut Crack Repair

- GT Exhaust Repairs

(Work Scope Summary)

| Work Description | Total Progress | Plan | Actual | Variance |

| IP Bypass valve replacement (P91) | 100% | 100 | 150 | + 50 |

| Condenser Strut Crack Repair | 100% | 100 | 110 | + 10 |

| GT Exhaust repairs | 100% | 100 | 100 | 0 |

| Total | 100% | 100 | 120 | 20 |

Project Resourcing

Workshop personnel included Coded Welders and Boilermakers. The support team included Project Management, Quality Management, Project Engineer and Project Supervisor.

Documents Supplied

- WPS & PQR

- Crew Qualification

- Online induction

- Completion Report

(Protech Welding Man Hours)

| Period | Man hrs | Achievement | Duration |

| Protech Welding | 500 | ZERO LTI & MTI | 12 Days |

(Health, Safety and Environment Performance (Inc. Subcontractors))

| No. | Description | Cumulative |

| 1 | Safety Interaction | 8 |

| 2 | Group Take 5’s | 50 |

| 3 | Passive Alcohol Test (Random) | N/A |

| 4 | Supervisor Site Walks | 15 |

| 5 | Critical Control Check | Ventilation Check |

Project Achievements

We’ve proudly completed the project with high standard performance on schedule.

All procedures were qualified and approved by International and Australian standards prior to the project commencement:

- Zero (0) Lost Time Incident during the project

- Zero failure rate on overall welding

- Project delivered on time and under budget

- Protech Welding Pty Ltd worked closely with the client nominated Site/ Welding Supervisor to ensure all project quality requirements were exceeded for the duration of the project

Activities

- Extensive interaction with our client to ensure quality of finished product was in line with practical requirements

- Project and quality management

- Constant communication with our client through work progress report on a daily basis

Work Photos