Protech Welding has developed the management system for the followings:

ISO 9001:2015 Quality

ISO 14001:2015 Environmental

ISO 45001:2018 Safety

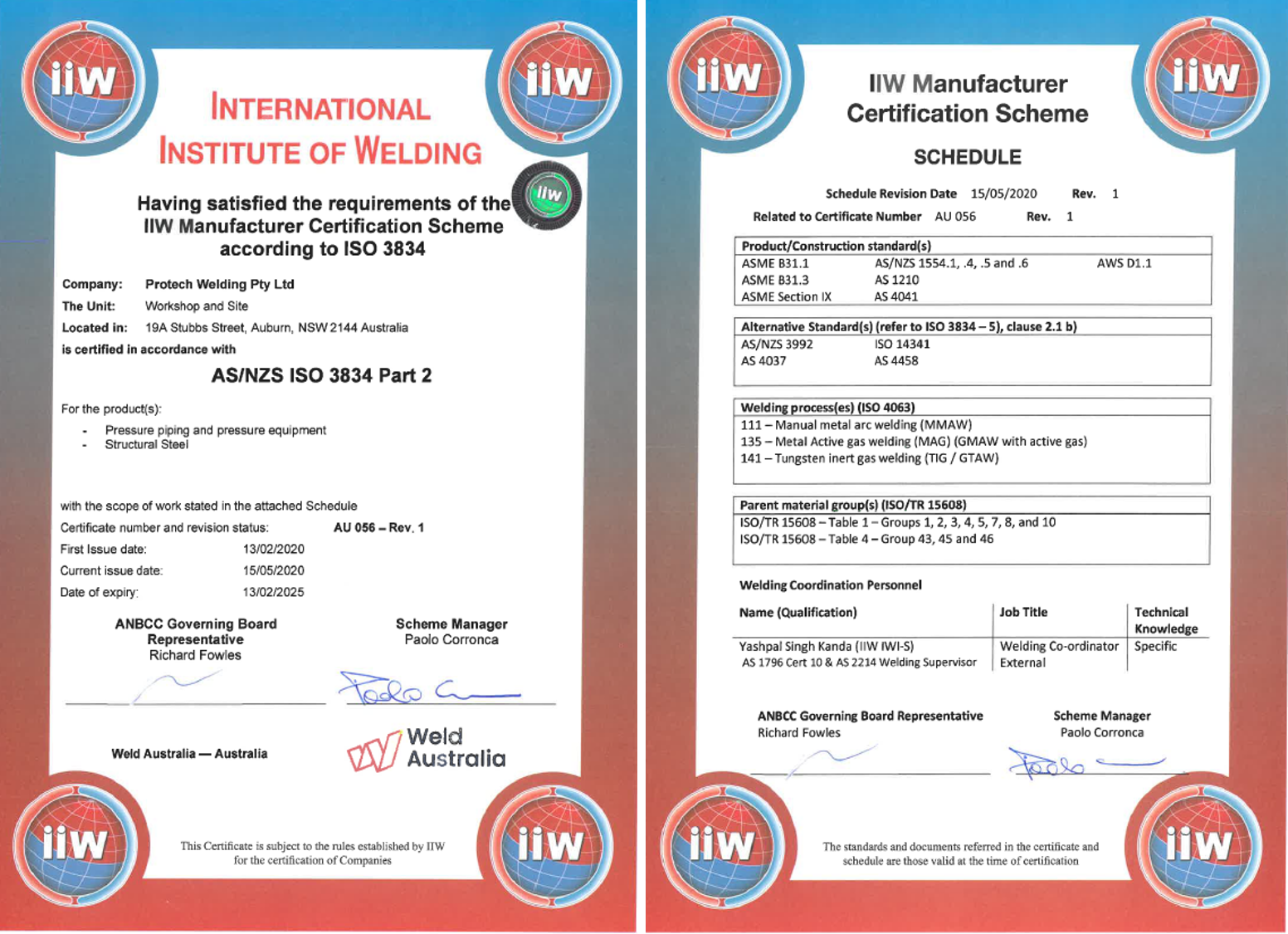

Protech Welding has developed the Factory Production Control System for the following:

- AS/NZS ISO 3834 Part 2: Comprehensive Quality Requirements

- Certificate No. AU 056

ANBCC 0072 – AU 056 Rev1 Protech 3834-2

Onsite Shutdown/Maintenance

Trust Protech for your next shutdown or maintenance project, our expert welders will get the job done.

Protech Welding carry out small & big projects by meeting the highest quality standards – ISO 9001, ISO 14001, ISO 45001, AS3834

- Construction Site – Commercial & Residental Areas

- On-site Shutdown – Oil & Gas Power Station

- On-site Maintenance – Renewable Energy Wind Farm

- On-site Fabrication – Tank Repair & Silo Repair

- On-site Labour – Railway & Light Rail

Our project management enables the job delivered on time while maximising work efficiency and performance.

Particularly, our project management includes:

- Logistic & Material Arrangement

- Tool Hire – A variety of ranges

- Packaging System

- Engineering & Design

- Program Procurement

- Quality Assurance

With the above aspects, Protech Welding is the One-Stop-Shop to minimise client’s burden & time.

Fabrication and Welding

Rely on our team of highly experienced fabricators and welders.

The team at Protech Welding have completed a broad range of customised fabrication and welding projects.

Not only welding experts but also engineering team can team up and solve the complex tasks in a short period of time, at the highest quality.

Our welding experts are 20+ years experience and the relevant NDE can be processed on request.

Workshops

Contact us about our Workshop Service for custom welding and fabrication projects.

Protech Welding has a fully equipped workshop with the capability to perform highly specialised and complex fabrication and welding tasks.

CORE COMPETENCIES:

• Scheduled Power Station Maintenance, Shutdowns & Turnkey Projects.

• Manufacturing of Heavy Structural (Workshop) & Onsite Installation.

• Spooling / Pipework (Workshop) & Onsite Installation

• Manufacturing of Light Components ie: Pipe Brackets / Bracings

• Custom Manufacturing & Fabrication with all Metals as per client’s specification.

Our team can fabricate materials ranging from CARBON STEEL through to EXOTIC METALS.

• Carbon Steel

• Stainless Steel

• Titanium

• Duplex (Super Duplex)

• CHROME (P11 , P22 , P91)

• Galvanised

QUALIFICATION:

- As a minimum, all of our registered welders have a valid Weld Ticket No. 4, No. 7 & No. 8, and Engineering (Fabrication) Certificate as standard.

- All 1st Class Boilermakers hold a valid Cert. 3 in Engineering (Fabrication Trade).

- All Advanced Riggers hold a valid Advanced Rigger Ticket.

- All tradesmen hold a valid High-Risk Work, Confined Space, Working at Heights / Elevating Work Platform and OH&S Induction (white card) Tickets / Certificates.

Training and Certification

We can help you with all of your training and certification needs.

Welding Coaching Program

Our training and certification services can be customised to you specific requirements, our expert trainers can assist you with your White Card, Working safely at heights, confined spaces training and certifications, Ticket7 and Certificate 3, which will assist you with basic welding skills and is a compulsory requirement a work places with white cards. We are also able to provide Coaching sessions to ensure that you are getting the right welding training and that your work is to standard.

White Card

Working safely at heights

Confined space

Certificate3

(Depends on experience, coaching sessions may be required)

– Learning basic welding skills

– Mostly compulsory at work place with white card

Special Package

A: White card + Confined space + Working at heights

B: Package A + Certificate3

The staff and trainers at Protech Welding pride ourselves in continued professional development, developing our skills and qualifications, and keeping our certifications current and up to date, to ensure that we are providing the best quality services and training for our clients.

*For certification fees, please contact us on 02 8386 2264, 0412 711 796

**For any other training requirements that don’t appear on this list please contact Protech Welding for more information.